- Home

- >

- Products

- >

- Oil Cylinder

- >

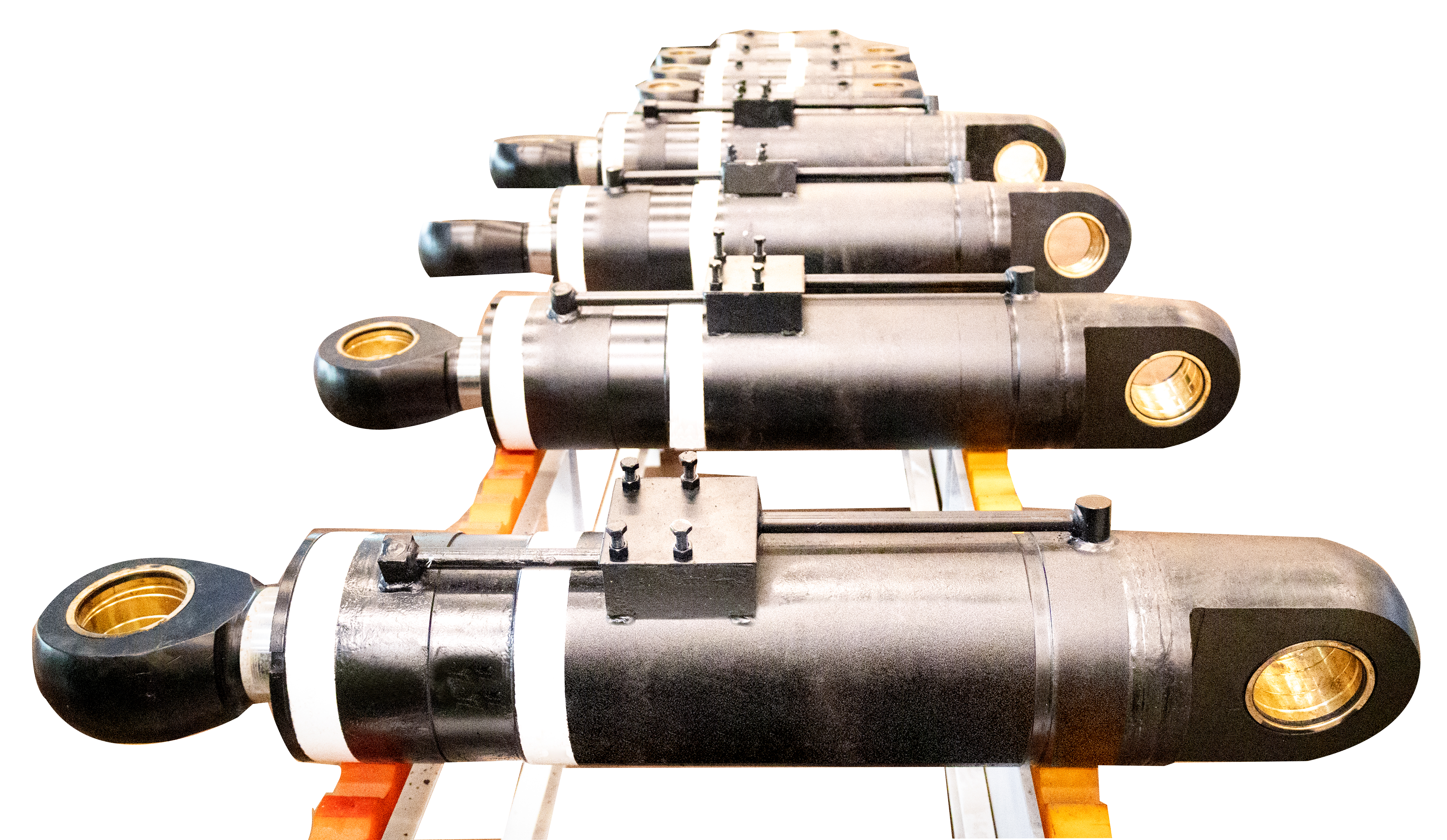

Oil Cylinder

1. The bottom of the heavy hydraulic cylinders for mining cylinder and the piston rod of the heavy hydraulic cylinders for mining are made of an integral forging process to increase the strength of the parts.

2. Imported original seals are used to increase the service life of the heavy hydraulic cylinders for mining, which can run for a long time without leakage and low failure.

3. The cylinder barrel, guide sleeve, piston, piston rod and cylinder bottom of the heavy hydraulic cylinders for mining are all made of 27Simn material, which is durable and wear-resistant.

- Liaoning Xinfeng

- Diaobingshan , Tieling Liaoning

- According to order quantity

- 100,000 pieces/year

- Information

Introduction of cylinder equipment for mining:

Heavy hydraulic cylinders for mining is an important actuator in the hydraulic system. The main function of hydraulic cylinders for mining is to convert hydraulic energy into mechanical energy to achieve linear reciprocating motion or swinging motion. The basic structure of hydraulic cylinders for mining includes cylinder barrel, cylinder head, piston, piston rod, sealing device, buffer device and exhaust device. Among them, the piston is the key component, which drives the piston rod to move linearly through liquid pressure to complete the mechanical action.

Application of hydraulic cylinders for mining:

1. Excavator: drive bucket, boom and slewing mechanism.

2. Loader: control bucket lifting and tilting.

3. Bulldozer/Road Roller: adjust the working height of the bulldozer or vibrating wheel.

4. Crane: support legs, telescopic boom.

5. Metallurgical equipment: pressing device of rolling mill, crystallizer vibration of continuous casting machine.

6. Automobile: dump truck lifting compartment (hydraulic lifting cylinder), truck tail plate.

7. Aerospace: landing gear retraction and extension, flight control surface drive.

FAQ of cylinder equipment for mining:

Q1. How to choose the right cylinder equipment for mining model? What parameters need to be considered?

A: When choosing cylinder equipment for mining, we can pay attention to the following parameters: load requirements, stroke length, working pressure, installation method and environmental adaptability.

Q2. What may be the reason for oil leakage in cylinder equipment for mining? How should it be solved?

A: If the cylinder equipment for mining leaks oil, it may be due to aging or wear of the seal. You can replace the O-ring, Gly ring, etc.; it may also be due to scratches on the piston rod surface. You can polish or replace the rod body.

Our advantages:

1. We have special CNC processing equipment for mining seal oil cylinder to ensure the processing accuracy of mining seal oil cylinder parts.

2. We have a special inspection test bench for mining seal oil cylinder to ensure that each mining seal oil cylinder is inspected and qualified before leaving the factory.

3. At present, our mining seal oil cylinder products have been involved in the fields of coal mines and engineering machinery, and can undertake customized products for customers.

4. Our mining seal oil cylinder uses high-precision cylinder barrels and high-quality piston rods, with strong pressure bearing capacity, large output force and stable movement.

About us:

We are a high-tech modern enterprise integrating independent research and development, equipment manufacturing, engineering services, equipment leasing, and sales services. We insist on using technology to bring changes to customers and realize mechanization, intelligence, and gamification of labor. Looking forward to your consultation!