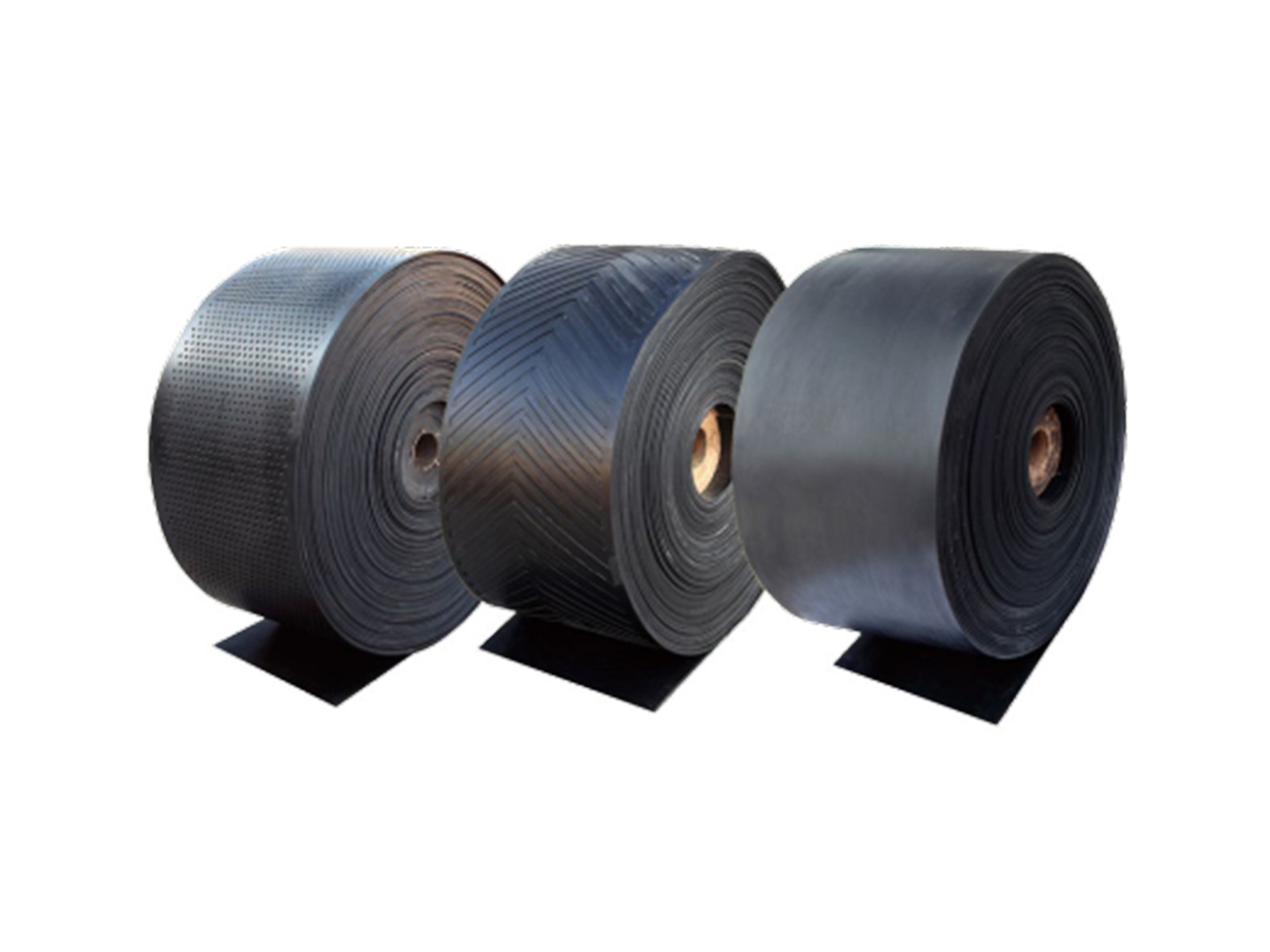

Flame Retardant Conveyor Belt

1. Fire resistant conveyor belts have strong bonding strength and are not easy to delaminate. The belt surface is smooth and uniform in thickness, with high tensile strength and tear resistance.

2. Fire resistant conveyor belts have good wear resistance, strong flame retardant and antistatic properties, and the quality and performance of flame retardant conveyor belts are stable.

3. Fire resistant conveyor belts have a high degree of production automation, with high mixers, grinders and other batching equipment, and are fully equipped.

- Liaoning Xinfeng

- Diaobingshan , Tieling Liaoning

- According to order quantity

- About 1000 units/year

- Information

Introduction of fire resistant conveyor belts:

Flame retardant coal mine conveyor belt is a special conveying equipment with fireproof, antistatic and flame retardant properties. It is mainly used in flammable and explosive environments such as coal mines, metallurgy, chemicals, and electricity to transport coal, ore, chemical raw materials and other materials. Our flame retardant coal mine conveyor belt is produced by advanced production lines, using excellent production formulas, equipped with drying boxes, slurry immersion tanks, electric heating plasticizing boxes, extruders, vacuum feeders and other automated equipment to maintain efficient and stable production.

Data of coal mining belt:

| Underground mining belts name | Specificationof coal mining belt | Belt width (mm) | Conveyor belt name | Specification | Belt width (mm) |

| Plastic surface solid core flame retardant conveyor belt (PVC) | 800s | 650;800;1000 | Rubber surface solid core flame retardant conveyor belt (PVG) | 800s | 650;800;1000 |

| 1000s | 650;800;1000;1200 | 1000s | 650;800;1000;1200 | ||

| 1250s | 800;1000;1200;1400 | 1250s | 800;1000;1200;1400 | ||

| 1400s | 1000;1200;1400 | 1400s | 1000;1200;1400 | ||

| 1600s | 1000;1200;1400 | 1600s | 1000;1200;1400 | ||

| 1800s | 1000;1200;1400 | 1800s | 1000;1200;1400 |

Features of fire resistant conveyor belts:

1. The flame retardant components of the flame retardant coal mine conveyor belt are evenly distributed and stable, and can maintain excellent flame retardant effects even under long-term operation and frequent friction.

2. The surface resistance and volume resistance of the flame retardant underground mining belts are low, which meets the requirements of anti-static performance in coal mines and avoids fire or explosion hazards caused by static electricity accumulation.

3. The flame retardant coal mine conveyor belt can be customized with different covering rubber thickness, bandwidth, cloth layer, and strength level according to customer needs, and is suitable for coal mines, tunnels, chemical industry, power and other environments.

Application of flame retardant coal mine conveyor belt:

1. Underground coal transportation: coal mine conveyor belt is suitable for long-distance main tunnels and underground mining belts mining working faces to prevent friction fires and gas explosions.

2. Coal washing plant: underground mining belts has flame retardant and anti-corrosion properties.

3. Metal mining: underground iron ore, copper ore and other transportation, underground mining belts prevents sparks from ore friction.

Classification of flame-retardant coal mining belts:

Flame-retardant coal mining belts can generally be divided into two types: PVC and PVG.The upper and lower covering layers of PVC flame-retardant coal mining belts are both PVC cover rubber, and the single-sided rubber is ≥1mm. The upper and lower covering layers of PVG flame-retardant coal mining belts are both nitrile rubber and PVC, and the single-sided thickness is 1.5mm-4.5mm. Both can be used for transportation above and below the coal mine.PVC flame-retardant coal mining belts are suitable for material transportation under dry conditions with an inclination of less than 16 degrees.PVG flame-retardant coal mining belts are suitable for the transportation of wet and mine conveyor belt watery materials with an inclination of less than 20 degrees.

Quality assurance:

We are equipped with a strict quality inspection system, with universal testing machines, viscometers, high resistance meters, thickness gauges, friction roller machines, combustion boxes, micro-controlled electronic tensile machines, rotorless vulcanizers and other precision testing equipment to ensure that all indicators of underground mining belts meet national standards.