- Home

- >

- Products

- >

- Mining Jack

- >

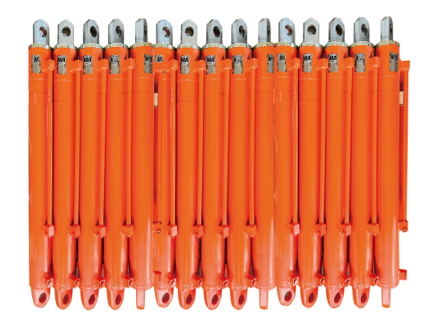

Mining Jack

1. The overall structure of the hydraulic mining jack is compact and easy to carry, especially suitable for narrow space operations.

2. The hydraulic mining jack can be customized according to the customer's usage requirements in terms of stroke, load, shape structure, interface mode, etc.

3. The hydraulic mining jack has a strong load-bearing capacity and is widely used in jacking, pushing, supporting and installation operations in mining, construction, transportation, power and other industries.

- Liaoning Xinfeng

- Diaobingshan , Tieling Liaoning

- According to order quantity

- 100,000 pieces/year

- Information

Introduction of hydraulic mining jack:

Jack for mining is a tool used to lift or jack heavy objects. The name mainly comes from its function, which can support and move heavy objects with less force. The principle of jack for mining is to use levers or hydraulic transmission systems to transmit force. The overall structure includes a top support seat or a bottom support claw, and a rigid jacking piece for carrying heavy objects. Design of hydraulic mining jack makes the jack for mining light and flexible during operation, and can be carried and operated by one person.

Features of the jack:

1. The main components of our jack for mining are made of high-quality high-strength alloy steel, with excellent properties such as high pressure resistance, impact resistance, and deformation resistance, ensuring the safety of use.

2. Our hydraulic jack for coal mines adopts advanced sealing structure to effectively prevent oil leakage and improve work efficiency and life.

3. Our hydraulic jack for coal mines is equipped with safety protection designs such as overflow valves and limit devices to prevent overload.

Application of jacks:

1. Vehicle maintenance: car/truck chassis inspection, tire replacement operations, 4S shop lift spare auxiliary jacking device.

2. Rail transit maintenance: train bogie jacking, subway track settlement adjustment.

3. Building installation reinforcement: precise positioning of steel structure columns, replacement of bridge bearings.

4. Formwork support system: cast-in-place concrete floor support, large slipform construction platform leveling.

5. Accident rescue: vehicle demolition support, earthquake ruins support.

FAQ of hydraulic jack for coal mines:

Q1. How long can the hydraulic jack for coal mines work continuously? Will it heat up or malfunction after long-term use?

A: Our hydraulic jack for coal mines is made of high-strength material and supports long-term continuous lifting or supporting operations.

Q2. Can you provide thin or small jacks? Suitable for use in confined spaces?

A: Of course. We provide thin hydraulic jack for mining machinery, hydraulic jack for mining machinery is specially designed for construction in limited spaces. It also has high load-bearing capacity and operational flexibility.

Q3. How to operate the hydraulic jack for mining machinery after it is transported to the site? Can ordinary workers get started quickly?

A: The structural design of the hydraulic jack for mining machinery is simple and practical. With our illustrated instructions or video tutorials, ordinary technical workers can operate it proficiently after simple training.

About us:

We focus on the research and development and manufacturing of intelligent equipment for coal mines, and have strong technical research and development strength and modern production capacity. The hydraulic mining jack we produce have strong lifting force, stable structure, good sealing, and convenient operation. They are widely used in various lifting, support and loading and unloading operations in fully mechanized mining working faces and are deeply trusted by industry users. Relying on the national technical platform and rich engineering service experience, we are committed to providing coal mining enterprises with safer and more efficient handling and support solutions.