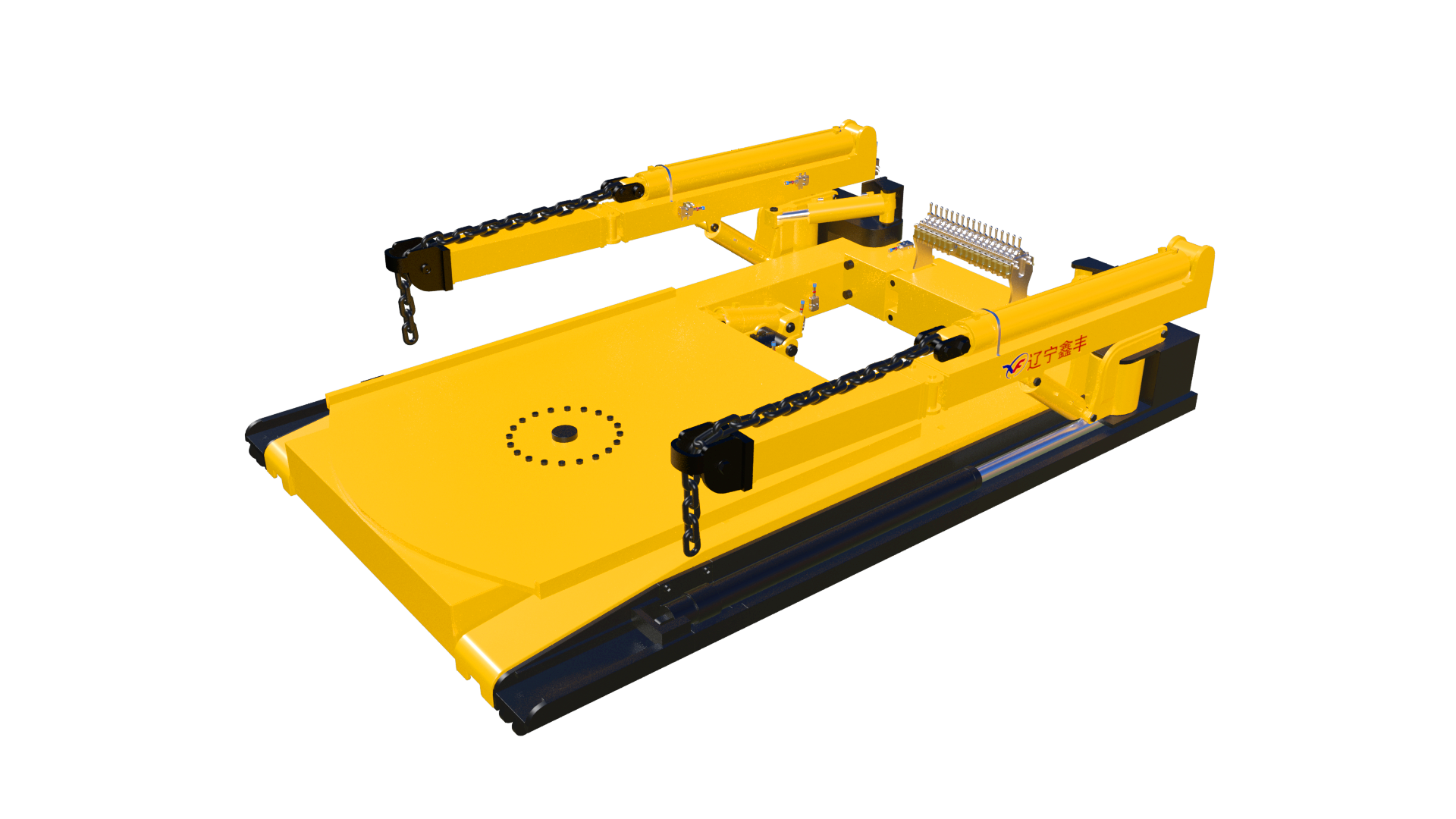

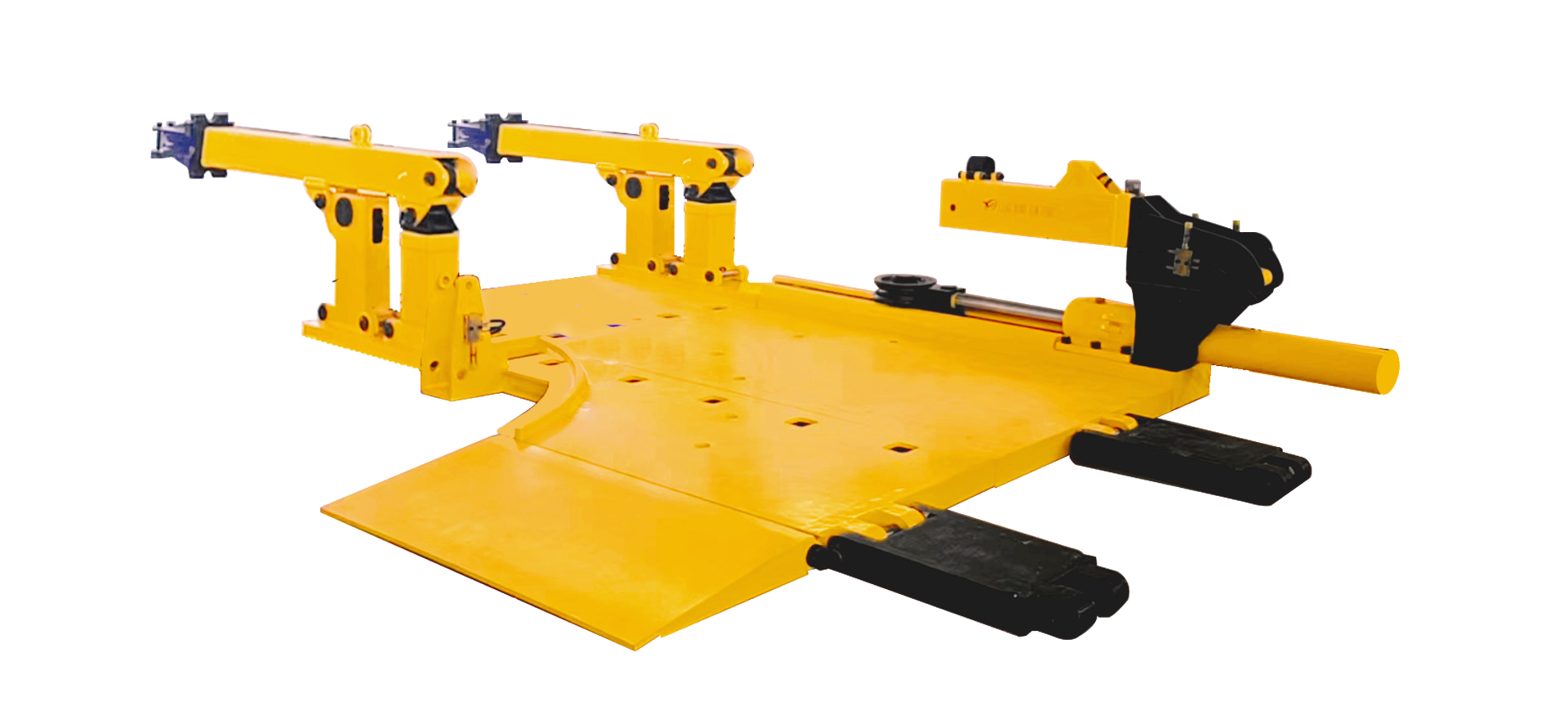

Adjusting Device Of Hydraulic Support(Transport Steering Platform)

1. Hydraulic support equipment for underground support transportation can complete the extraction, steering and loading of supports at one time.

2. Hydraulic support equipment for underground support transportation can be manually controlled or remotely controlled, and can be flexibly operated according to the on-site conditions.

3. Hydraulic support equipment for underground support transportation supports 90-degree turning and multi-angle direction adjustment to achieve precise positioning of hydraulic supports.

- Liaoning Xinfeng

- Diaobingshan , Tieling Liaoning

- According to order quantity

- About 1000 units/year

- Information

Introduction of hydraulic support underground transportation equipment:

Hydraulic support equipment for underground support traction is a special equipment installed in front of the backscatter support for the extraction, adjustment and loading of the hydraulic support from the working surface. The transport steering platform is equipped with a retractable working arm that can lay and recycle modular tracks. It changes the traditional method of manually laying the backscatter track and reduces the physical labor of employees. At the same time, the middle trough of the conveyor can also be withdrawn.

Features of hydraulic support equipment for underground support traction:

1. Hydraulic support equipment for underground support traction replaces the traditional method of withdrawing the support using a winch in combination with a guide pulley, eliminating the potential safety hazards caused by winch wire rope traction.

2. Hydraulic support equipment for underground support traction is used in conjunction with shield support to withdraw, turn and load the hydraulic support from the working face. The power source comes from the working face hydraulic system.

3. Hydraulic support transfer device (traction and direction adjustment platform has fewer connecting rods and greater traction force, which solves the problem of hydraulic supports being crushed during the withdrawal process.

Main technical parameters of hydraulic support underground transportation equipment:

Item | Technical Parameter | Unit |

Model | TYH-600 | |

Rated Traction Force | 600 | t |

| Nominal hydraulic pressure | 31.5 | MPa |

Working Dimensions(Length × Width × Height) | 4850 × 2980 × 1220 | mm |

| Mine lowering dimensions(length × width × height) | 3120 × 1810 × 250 | mm |

Crawler | 1500 | mm |

Lifting height behind pallet | 300 | mm |

Turntable rotation angle | 360 | ° |

Horizontal arm rotation angle External | Outer: 42 Inner: 30 | ° |

| Vertical deflection angle of boom | Up: 30 Down: 5 | ° |

| Machine weight | 13500 | kg |

Application of hydraulic support underground transportation equipment:

1. Initial mining installation: In the initial mining stage of the fully-mechanized mining face, the new hydraulic support is pulled from the assembly chamber or transportation tunnel to the designed position of the working face, and adjusted to the correct direction (such as the support top beam is perpendicular to the coal wall).

2. Final mining withdrawal: At the end of the mining of the working face, the old support is dragged out of the working face to the support withdrawal channel, and the direction is adjusted for loading and lifting.

3. Quick replacement of the support: When individual supports are damaged, it is used for temporary removal and replacement of new supports.

4. Shifting of components of coal mining machines and scraper conveyors: used for short-distance traction and direction adjustment of large components such as coal mining machine drums and motors underground.

FAQ:

Q1. What are our main products and services?

A: We are mainly engaged in the research and development, manufacturing and services of equipment related to fully-mechanized mining working faces in coal mines, including but not limited to underground transportation equipment mining hydraulic cranes, hydraulic support installation forklifts, hydraulic support removal forklifts, hydraulic excavators for coal mines, etc.

Q2 Do we have independent research and development capabilities?

A: Yes. We attach great importance to scientific and technological innovation and have a national-level "Coal Machinery Industry Comprehensive Mining and Reclaiming Engineering Technology Research Center" and intelligent laboratory.

Q3 What qualifications and certifications does our company have?

A: We have many qualifications including coal safety (MA) certification, explosion-proof certificate, ISO quality management system certification, etc. Our products fully comply with national coal mine safety standards and export technical requirements. At the same time, the company has independent intellectual property rights and patented technologies on many equipment and systems.