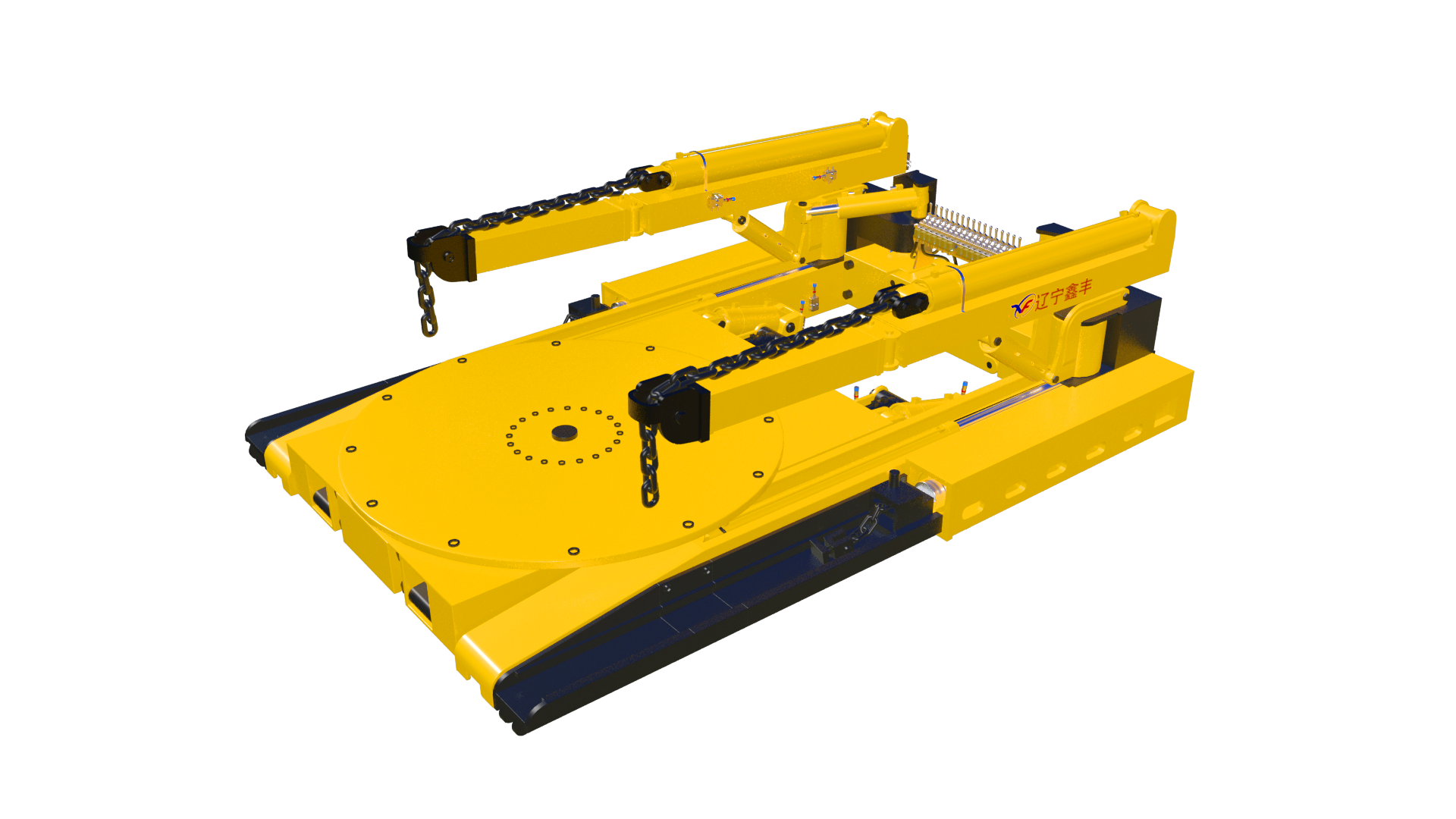

Adjusting Device Of Hydraulic Support(installation Forklift Truck)

1. Forklift for installing underground support only needs to be installed once, and the operation is flexible and convenient.

2. Forklift for installing underground support is used in conjunction with the traction power device, which can realize the installation of large slope and large tonnage equipment.

3. Forklift for installing underground support is equipped with an anti-dumping device to improve the safety of bracket installation.

- Liaoning Xinfeng

- Diaobingshan , Tieling Liaoning

- According to order quantity

- About 1000 units/year

- Information

Introduction of forklift for installing underground support:

The hydraulic bracket mine installation forklift is towed by a rack locomotive, and the bracket is transported and installed along the combined track in the cut eye. The mine installation forklift can realize automatic unloading, steering and positioning of the hydraulic bracket. The mine installation forklift is equipped with a telescopic working arm, which can lay and recycle the combined track, changing the traditional manual laying and recycling of the track, and reducing the physical labor of the workers. At the same time, the mine installation forklift can also install the middle trough of the conveyor.

Features of hydraulic support underground mining forklift:

1. The main structure of the hydraulic support mine installation forklift is made of high-strength alloy steel, which is impact-resistant and bending-resistant and can adapt to heavy-load operation requirements.

2. Hydraulic support underground mining forklift is hydraulically controlled, with the characteristics of simple operation, smooth operation, quick installation and safe walking.

3. Hydraulic support underground mining forklift has strong working ability and truly achieves efficient, fast and safe effects.

Main technical parameters of hydraulic support underground mining forklift:

Item | Technical Parameters | Unit |

Model | TYA - 800 TYA - 600 | |

Rated Tractive Force | 800/600 | mm |

Track Gauge | 1500 | mm |

Working Dimensions (Length×Width×Height) | 4900×2650×1500 4500×2540×1450 | mm |

Dimensions for Shaft Entr(Length×Width×Height) | 4500×700×470 2665×1885×310 | mm |

Lifting Weight of Lifting Arm | 5 | t |

Lifting Height behind the Pallet | 450 | mm |

Rated Hydraulic Supply Pressure | 31.5 | Mpa |

Rotation Angle of Turntable | 360 | ° |

Horizontal Swing Angle of Lifting Arm | Outer: 42 Inner: 30 | ° |

Vertical Swing Angle of Lifting Arm Upper: | Upper: 30 Lower: 5 | ° |

Total Machine Weight | 15000/13000 | kg |

Purpose of underground mining forklift:

Used for transporting and installing brackets and other equipment.

Performance of underground mining forklift:

Use the hydraulic system of the working surface to lift and lock the equipment. It can be operated manually or remotely.

About us:

Liaoning Xinfeng Mining (Group) Co., Ltd. was established in November 2004. It is a high-tech modern enterprise integrating independent research and development, equipment manufacturing, engineering services, equipment leasing and sales services. The company has a high-quality and efficient professional team, with the ability to undertake domestic and foreign mine excavation, coal mining, equipment installation, equipment maintenance and other construction. The company insists on shaping a famous brand with high-quality products and pursuing sustainable, healthy and steady development with innovative brand development.