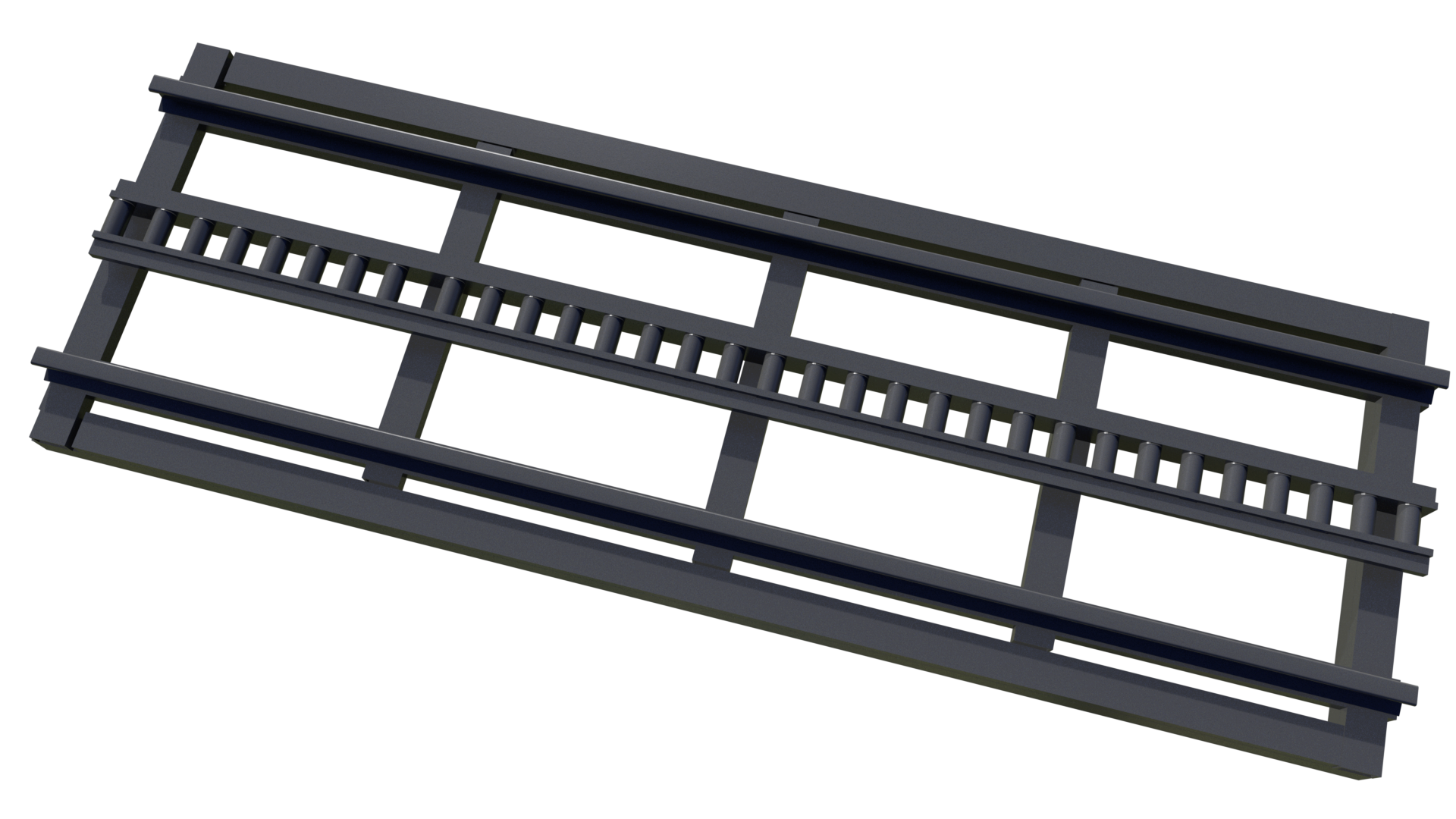

Underground Track Of Coal Mine

1. The tooth row of Railway for coal mine is welded with high-strength steel, which has high strength and no deformation, forming an anti-derailment device.

2. Railway for coal mine does not need to dismantle the original track, realizing ropeless transportation, which is safe and efficient.

3. Railway for coal mine cooperates with explosion-proof diesel locomotives for transportation.

- Liaoning Xinfeng

- Diaobingshan , Tieling Liaoning

- According to order quantity

- : About 1000 units/year

- Information

Introduction of railway for coal mine:

Railway for coal mine is a track based on modular design concept specially used for the operation of rack locomotives in tunnels. Coal mine track is welded with frame structure and heavy rails. Its core feature is flexible combination through standardized and interchangeable components to meet the needs of different scenarios. Using coal mine track can prevent derailment and rollover accidents of vehicles during transportation and ensure the safety of personnel.

Features of coal mine track:

1. The unit module of coal mine track can be transported, disassembled and replaced separately, reducing transportation and maintenance costs and improving the overall maintainability of the system.

2. The underground locomotive track adopts precise structural design combined with high-strength materials to ensure the safe and stable operation of the system under heavy load or complex working conditions.

3. Underground locomotive track can be customized according to customer needs, suitable for special track gauge, turning radius, slope and other personalized design requirements.

4. Underground locomotive track can be used for a long time in harsh environments such as high temperature, humidity and corrosion.

Data of coal mine track:

| Name | Technical parameters | Unit of measurement |

| Dimensions (length × width × height) | 3000 × 1400 × 168/194 | mm |

| Track type | 30/38 | kg/m |

| Track width | 600/900 | mm |

| Single section laying inclination | ≤3° | ° |

| Weight per section | 640/710 | kg |

Classification of underground locomotive track :

Dynamic module track:It is suitable for special tracks with a track gauge of 600 or 900mm, which can be used underground or on the surface, and is used in conjunction with explosion-proof diesel locomotives for transportation operations.

Static module track: The rack rail is welded with high-strength steel, which has the characteristics of high strength and no deformation, forming an anti-derailment device. Ropeless transportation can be achieved without dismantling the original track, which is safe and efficient.

Application of underground rails for coal mines:

1. Temporary construction track: Coal mine track provide flexible paths for mobile cranes or material transport vehicles in large construction sites (such as bridge and tunnel construction).

2. Modular building transportation: Underground rails for coal mines are used for sliding or translation installation of prefabricated building modules.

3. Temporary rail transit: Underground rails for coal mines serve as temporary light rail or tram lines for short-term activities such as event venues and expositions.

FAQ:

Q1. How durable is it? Can it adapt to the coal mine environment?

A:Railway for coal mine adopts high-strength explosion-proof design, wear-resistant and corrosion-resistant, and fully adapts to the underground working environment with high humidity and high dust

Q2. Does it meet safety standards?

A:Coal mine track has passed the national coal mine safety certification to ensure operational safety.

Q3. How is the production efficiency? Is the energy consumption high?

A:Underground rails for coal mines adopts high-efficiency energy-saving design, the processing capacity meets the demand, and coal mine track is equipped with an intelligent control system to optimize energy consumption and reduce operating costs.